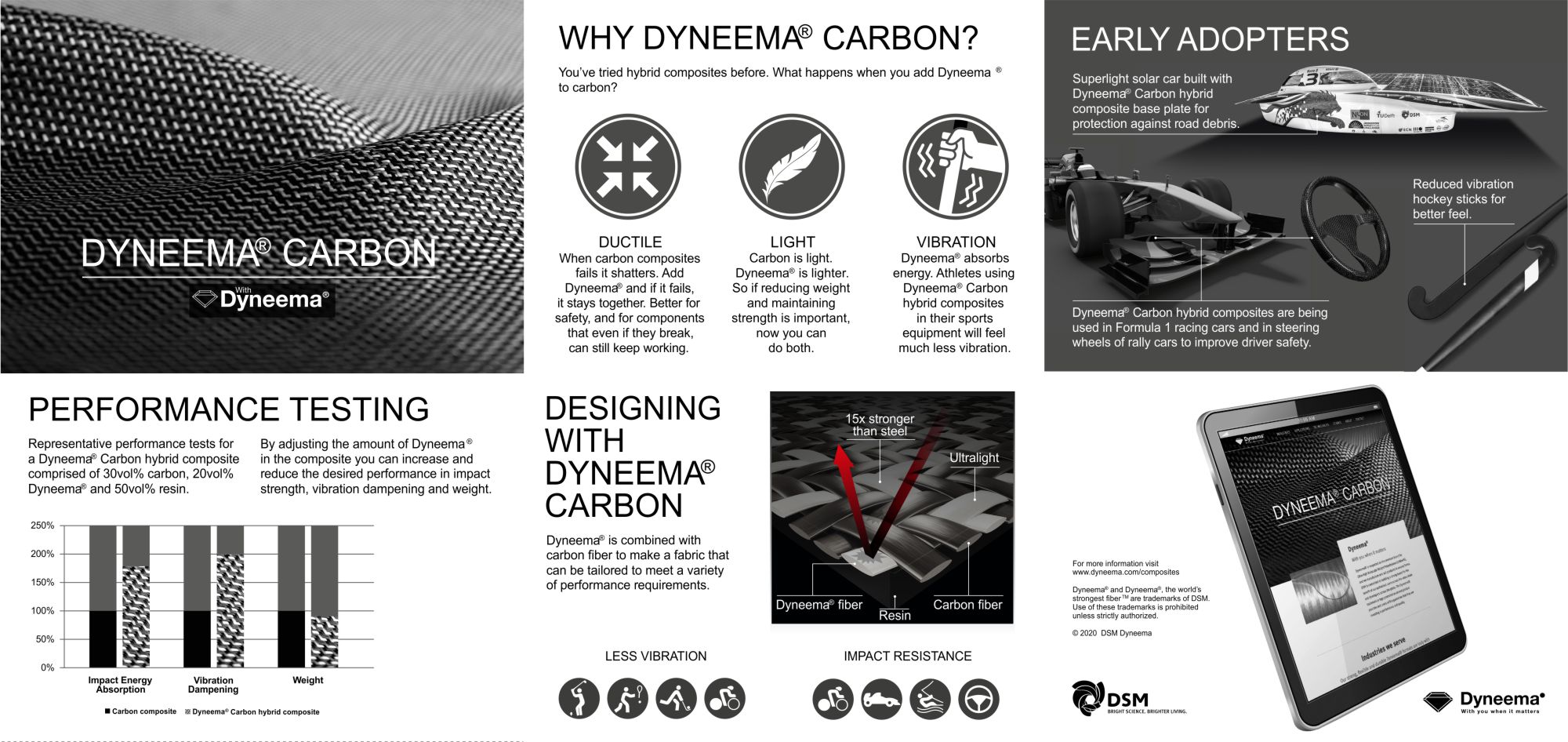

Topside - 3K Carbon fiber , high modulus lamination.

Underside - High Modules Carbon fiber at 45 degree's x2 to the twintip's length , 100% of the carbon fiber is being torsion-ally used. This is the highest strength to weight ratio possible.

Topside - "X" pattern carbon strips control any torsional movements holding the concave and under-shape true under jumping and hard railing pressures.

Impact resistance with Kevlar inner core mixed with S-Glass pre-tensioned fiber glass.

Hybrid Airex-wood core , cnc shaped with stainless steel M6 inserts.

Kiteboard weight is custom controlled to the riders weight , a heavier rider requires a stronger twintip , hence the board is built with more reinforcements.

A lighter weight rider has less reinforcements so a lighter weight kiteboard , A Lightwind-Pro for a 70 kilo rider can weigh 1,95 kilos with a safety factor of 200% , twice as strong as the board needs to be.

Epoxy sanding and finishing coats top and underside , these finishing coats are durable with a high surface hardness.

Graphics

The top and underside of the Lightwind Pro are hand laminated with carbon fiber as part of the actual structure of the board. The carbon fiber is gel-coated to ensure a perfectly flat surface.

We attach masking paper with digitally cutout logos to this surface, then spray these cutouts in whatever color we choose. The "Lightwind Pro" is sold with the standard graphics set. Customers may choose from other Nomad designs or create their own, additional charges may apply.